Industrial

Warehouses

Manufacturing Plants

Warehouses

Manufacturing Plants

At Happy Valley Concrete Coatings, we offer customized flooring solutions for various industrial spaces, including warehouses and manufacturing plants. We ensure minimal downtime and successful coating application every time through our wide range of coatings and industrial equipment. Our team works with you from start to finish to guarantee a smooth installation process and allows you to get back to business as quickly as possible.

Our team is experienced in high quality, industry leading standards of floor preparation. Our specialized equipment is designed to prepare the floor by removing damaged or deteriorated concrete, open up porosity, and remove all chemicals and contaminants. The resulting coarse profile allows the coating to deeply penetrate the concrete, ensuring maximum adhesion.

We focus on concrete restoration, replacement and coating. Providing a fresh, new floor that is ready to be walked on in 24 hours. We offer expansive and efficient concrete coating flooring using V-8 floor resin systems for industrial clients in Carlisle, State College, Spring Mills, Harrisburg, Williamsport, Williamsburg, Mechanicsburg, Centre Hall, Mill Hall and beyond.

Guaranteed Benefits

Superior Product

As certified V-8 coating installers we can guarantee that we are using the superior concrete coating product for your warehouse, plant or industrial facility.

Expert Installation

You can be certain that your flooring will be properly installed with our certified and trained installation specialists.

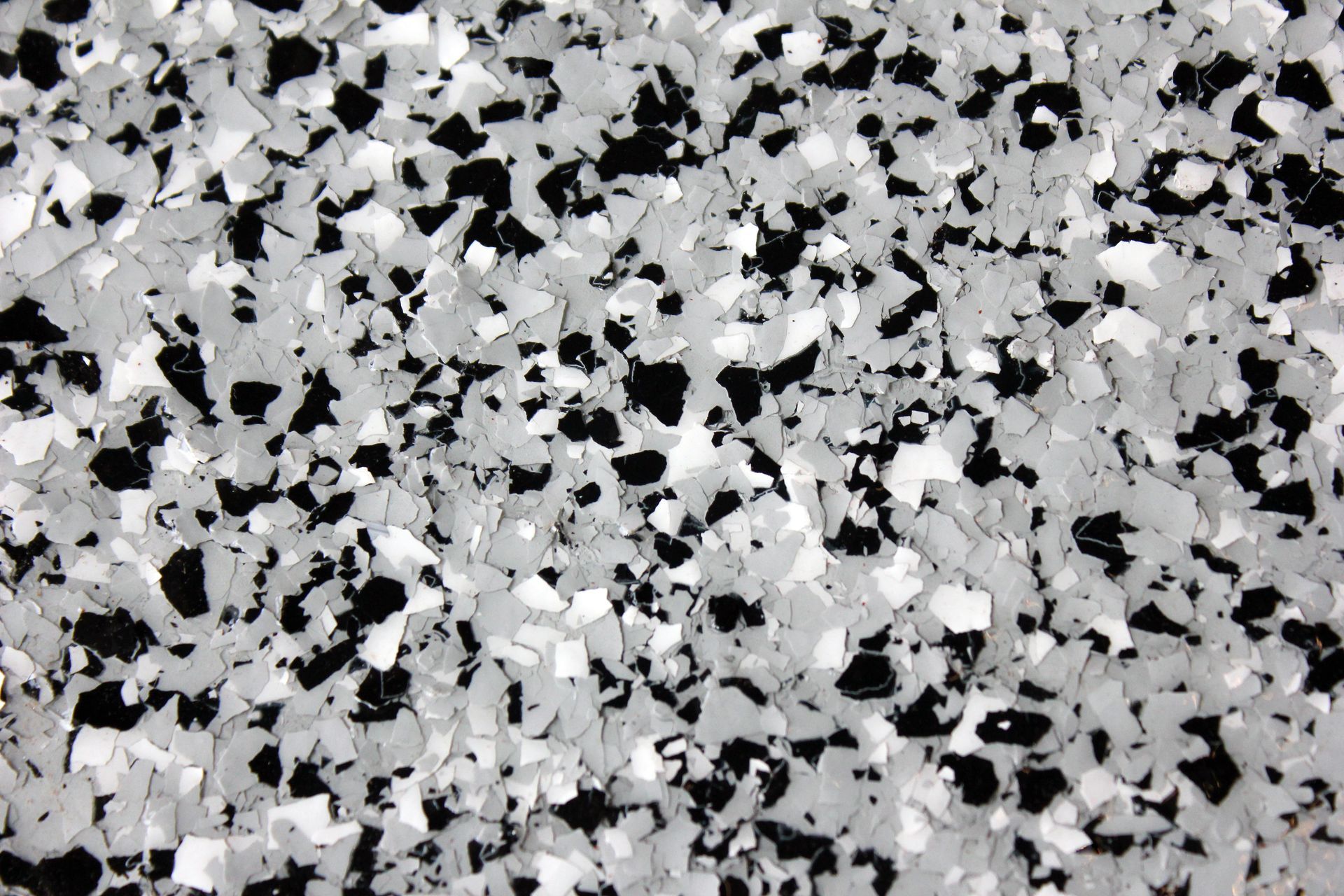

Custom Colors & Style

We offer customized color options to match your branding, facility needs and preferences.

Easy Cleaning

Our low-maintenance coating will keep your floors free of mold and mildew build-up.

OUR PROCESS

Substrate Preparation

At Happy Valley Concrete Coatings, we understand that proper concrete preparation is crucial to the success of your flooring installation. Our team will start by examining your floor’s density, hardness, moisture content, and structural condition to determine the best approach. We use the number one form of preparation in the coating industry, cleaning and levelling for the maximum adhesion and smooth finish.

Concrete Repair and Restoration

In the case of many floors, we have to use special menders and fillers to fix any pits, cracks, and/or spalls present in the existing concrete floor. This portion of the process includes grinding, mending and filling. We remove any deteriorated concrete and overfill it with our mender material. When the material is fully cured, we grind the overfilled material flush with the concrete surface.

Floor Coating Installation

We start by coating all vertical surfaces, including the concrete or block stem walls, steps, and walls as defined in the scope of the project. We mix and apply our base coat to the floor. The high solids content provides the strongest and most densely cross-linked product ensuring strength, durability, and longevity of the floor coating. Once the base coat is applied, your choice of polymer flake, metallic finish, quartz, solid color or clear is broadcast onto the floor, covering it fully. The drying period on our base coat is typically a 60-90 depending on the temperature and humidity the day of the install.

Once the basecoat is fully cured, if flake was chosen, we scrape the floor to remove any loose or vertically standing flakes. We then vacuum to recover any loose chips left behind on the floor.

Finally, we apply the clear topcoat with a squeegee and back and cross-roll to eliminate lines and leave an even clear coat over the entire floor. Texture can be added to the topcoat for added slip-resistance.

Quick Links

Applications

All Rights Reserved | Happy Valley Concrete Coatings

All Rights Reserved | Happy Valley Concrete Coatings

This site is designed, hosted & maintained by siteROOST | Privacy Policy